I. Product Information

This machine is suitable for paste liquid filling such as tomato paste, honey, jam, gel,peanut butter, oil , shampoo, lotion, cream, etc. The automatic tomato sauce filling machine adopts Japanese Mitsubishi PLC program system to control. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision. The hopper and the piston pump can be heated and keep warm.

Features:

1. Adopting the world-famous brands, like Japanese Omron light control element and Japanese SMC pneumatic components,

2.Speed control: frequency conversion adjusting speed

3. The automatic paste filling machine is designed according to GMP requirements, which is made of stainless steel under the international of SUS316L, SUS304.

4.It adopts no bottle no filling system. Unique drip proof device in production process, ensure no irrigation constant filling function.

* It's design compact and reasonable, the appearance is artistic.

* Control System- Mitsubishi PLC control system, random change filling volume.

* Control Panel- Colorful screen, easy-operated, stable and reliable

* Function Improvement- The filling nozzle is equipped with filling blocker. This machine can realize diving filling according to the material properties. (this function can be selected)

* Real-Time Alarm- Automatic alarming when the fault happens, automatic stopping and alarming when the system appears serious breakdown.

* Performance Improvement- Adopting international famous brand to ensure the remarkable quality, stability and high precision.

* Machine Elements- The parts contacted with the material use the high grade SS 304 and non-poisonous. ( Could be SS316 if required )

* Expansion Function- We can carry out special configuration according to customers' requirements. (airtight, heating, sterilizing etc)

* Counting Detection- Real-time counting, reflecting the output directly.

* Filling Detection- No-bottle, no filling, it will not conduct filling if the bottles are not enough.

* Maintenance Condition- Fully comply with the GMP requirements, easy to disassemble and clean.

* Environmental Protection Configuration- Equipped with eco-friendly frame, realizing more cleaner and sanitary operating environment function and more precise filling measurement.

* Changing Specification-No need to change any components, easy to realize changing the bottle types by simple adjusting

Special Design

Controlling system

full-auto PLC + human-computer touch screen control system

Bottle position correct device

a special bottles position device is added to make the whole filling process smooth and stable

Filling nozzles

with the function of anti-drop and anti-drawing

Piston pump

suitable for all kinds of material with high filling speed and filing precision, For filling corrosive, the position pump will be made by silicon rubber, Teflon, ceramics and other corrosion resistance materials.

Cleaning

the pump uses quick-fit removal Structure: easy cleaning and disinfection.

Protector

It's optional for customers it's dust proof ,

can protect the products being polluted when filling

II. Technical Data

Item

Automatic paste liquid filling machine

Production capacity

1000-6000bottles/hour

Filling volume

5-100ml 10-300ml 50-500ml 50-1000ml 300-2500ml 1000-5000ml

Filling nozzles

2,4,6,8,10,12

Filling accuracy

±1%

Air pressure

0.4-0.6Mpa

Machine weight

550-650kg

Power

220v or 380v

Warranty

one year

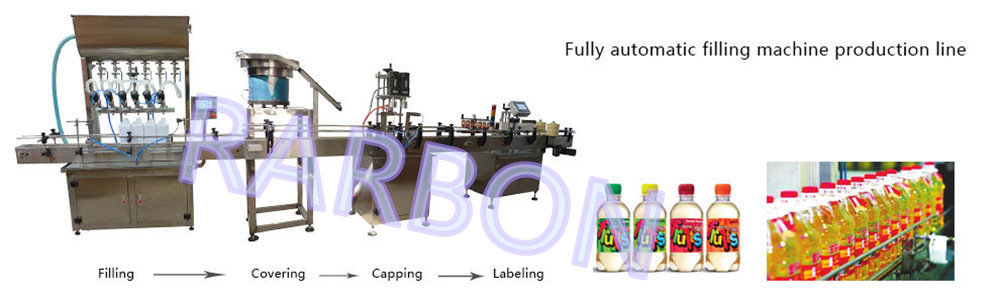

III. Product Show

Suitable for tomato sauce, cream ,butter ,sesame paste etc filling

recommend

double nozzle lubrication oil weight filler with lid pressing 0

Alibaba china supplier semi auto big bucket coating paint weighing filling machine for sale 0